We have been importing and exporting since 1997.

We have been operating in the field of Electric Gantry Crane Machinery since 2005.

So far, we have been successfully exporting to 44 countries in the world and successfully meeting their demands. We follow the needs of these 44 country markets. We also offer them Turkish products. We also have sufficient experience in the psychology, culture and trade of the people of these 44 countries. We have developed our strategy against all kinds of problems.

Manufacture in 2018

Happy Clients

Projects

Hours Of Support

Hard Workers

Product

Featured Services

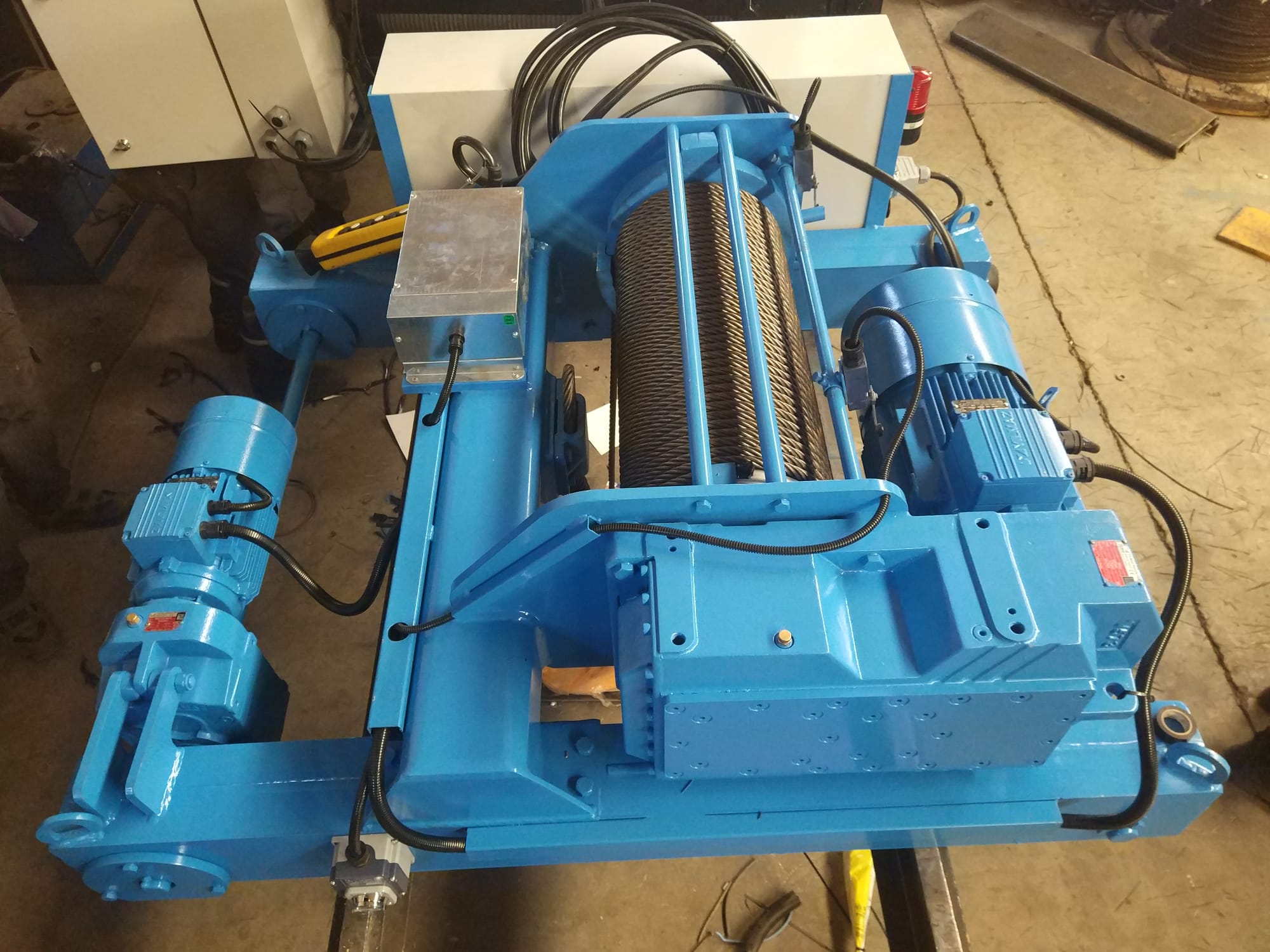

Electric rope hoists are the superior equivalents of our trolleys with aesthetic appearance and performance values, which is a crane designed as GNCDG series.

Monorail GNCSG is a type of crane system that is designed to operate on a single rail or track. It is commonly used in industrial settings for material handling and transportation.

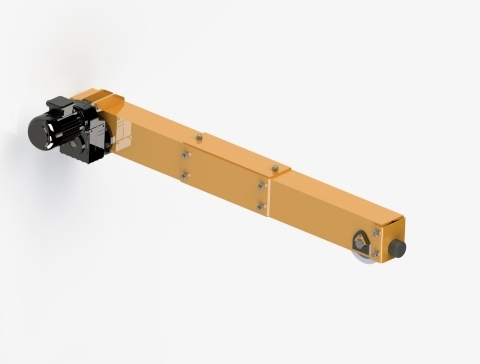

Monorail overhead single girder endcarriages are used to move the monorail overhead single girder cranes.

UNDERSLUNG

Underslung cranes are a type of crane system that is designed to operate in low headroom environments.

UNDERSLUNG ENDCARRIAGES

Underslung cranes are a type of crane system that is designed to operate in low headroom environments.

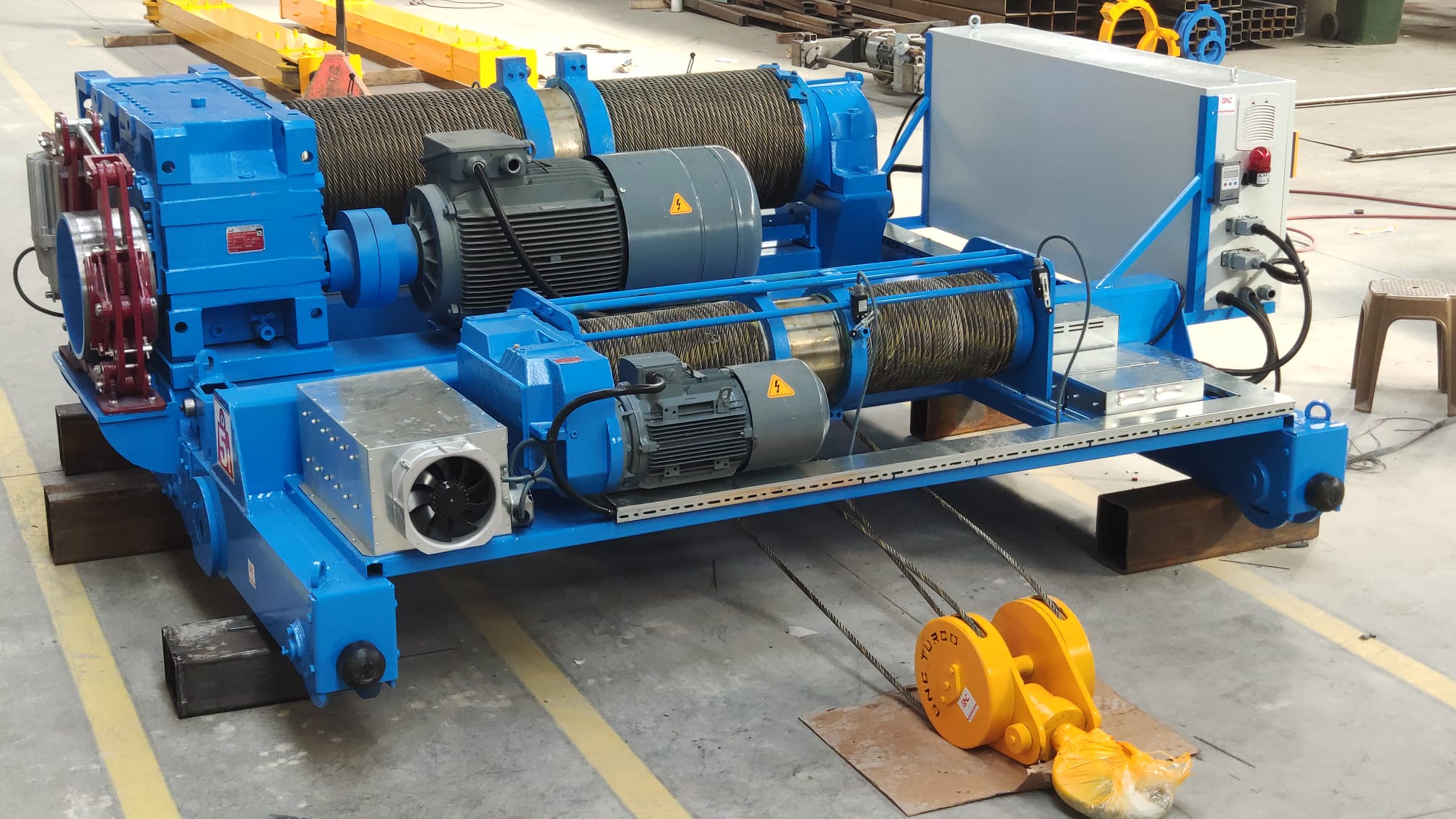

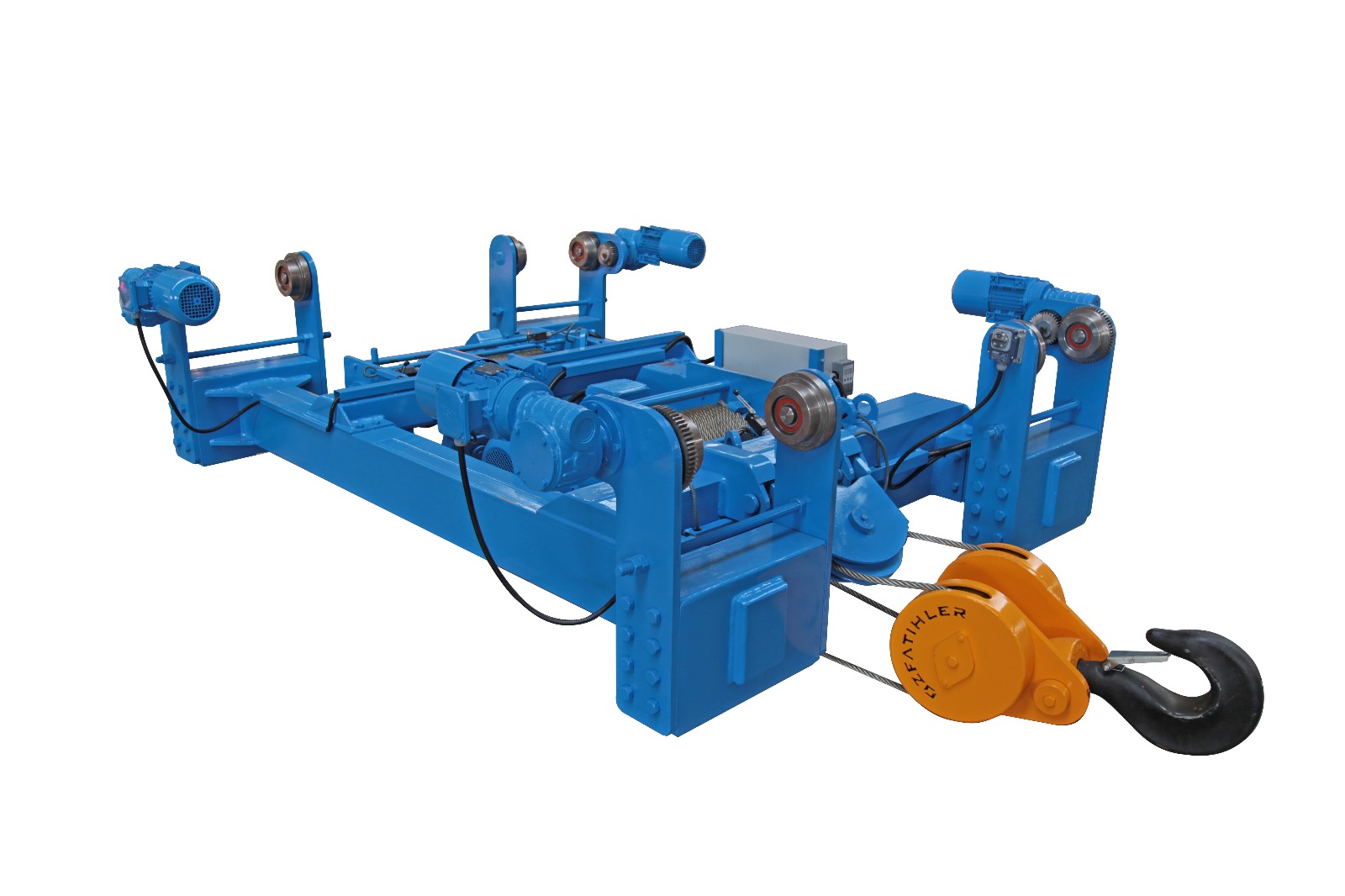

DOUBLE GIRDER OVERHEAD CRANE

Due to cost, easy maintenance and repair, unlimited capacity, unlimited dimensions and the ability to design and manufacture in desired features, double girder electric overhead cranes are seriously preferred and used in all sectors..

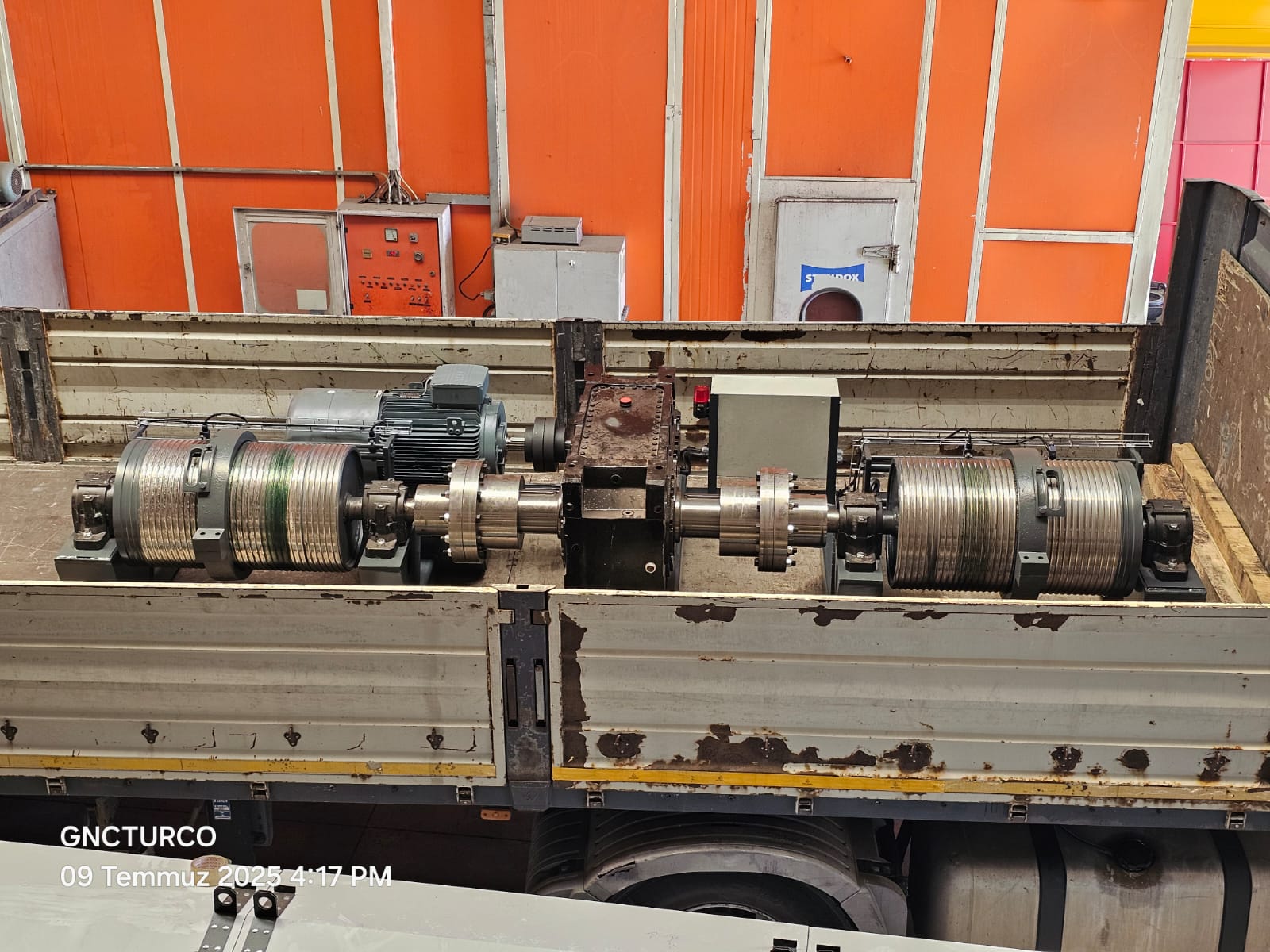

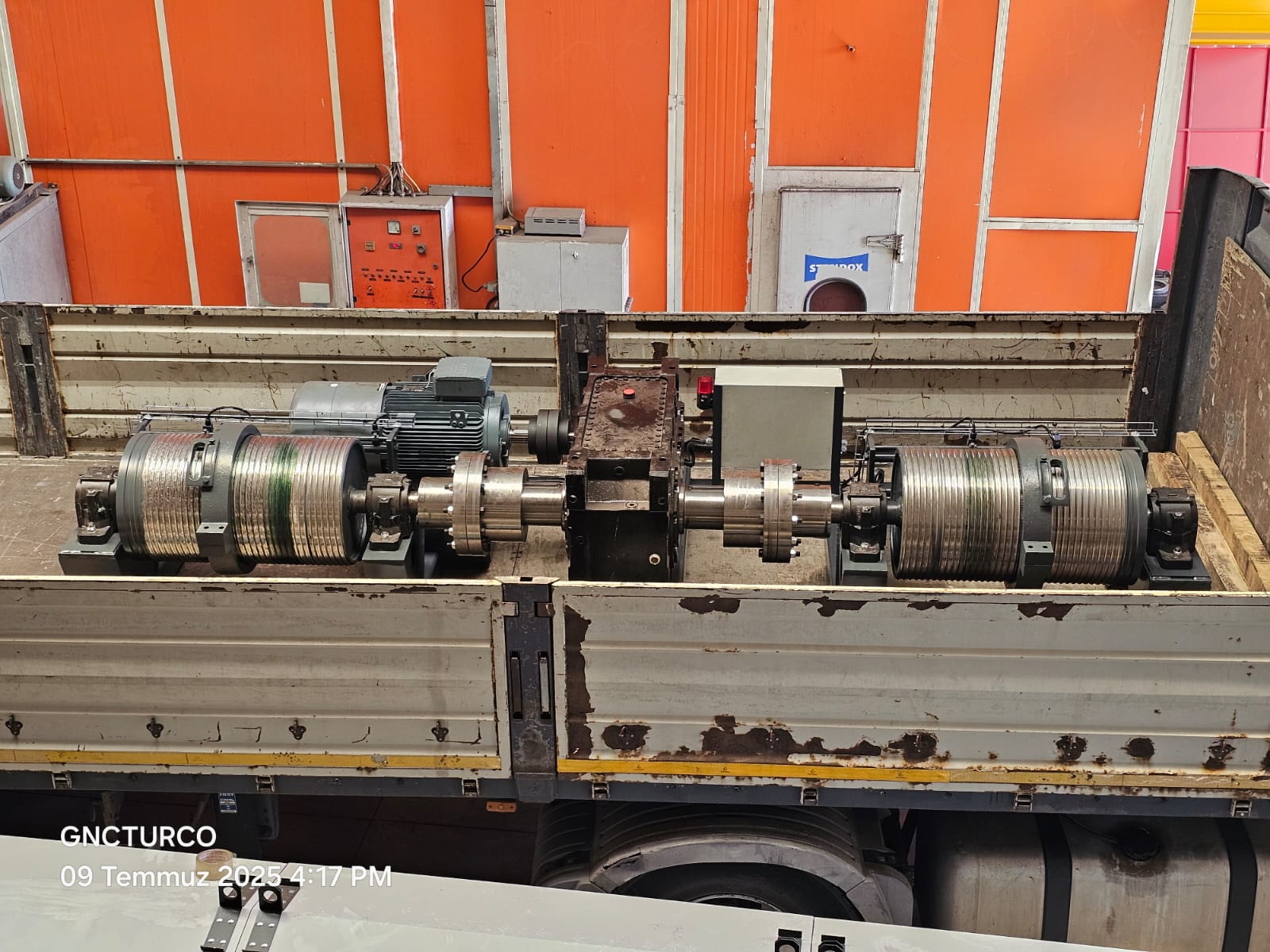

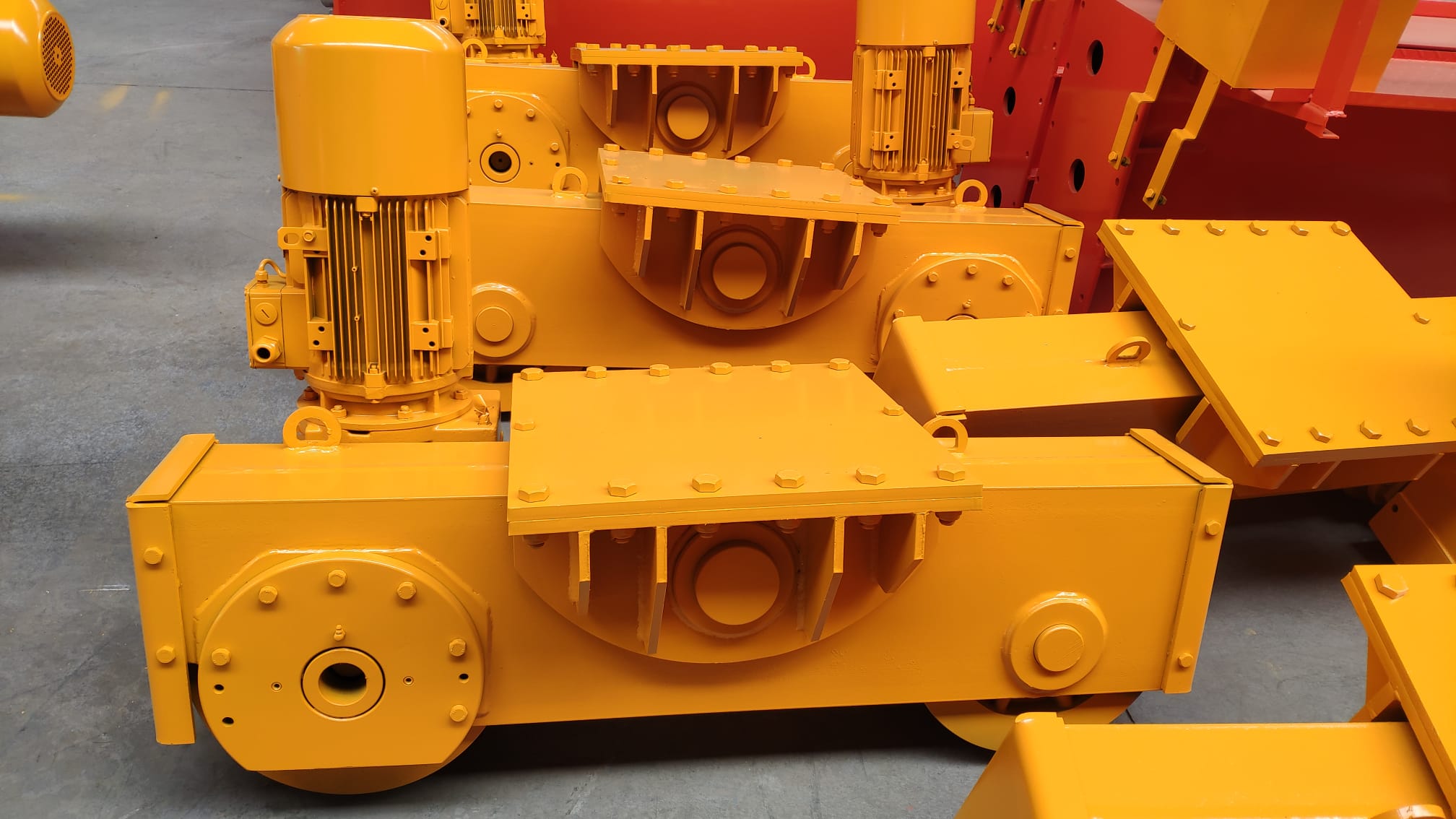

DOUBLE GIRDER OVERHEAD ENDCARRIAGES

Overhead double girder endcarriages are a type of crane system that is designed to support heavy loads and provide stability during operation.

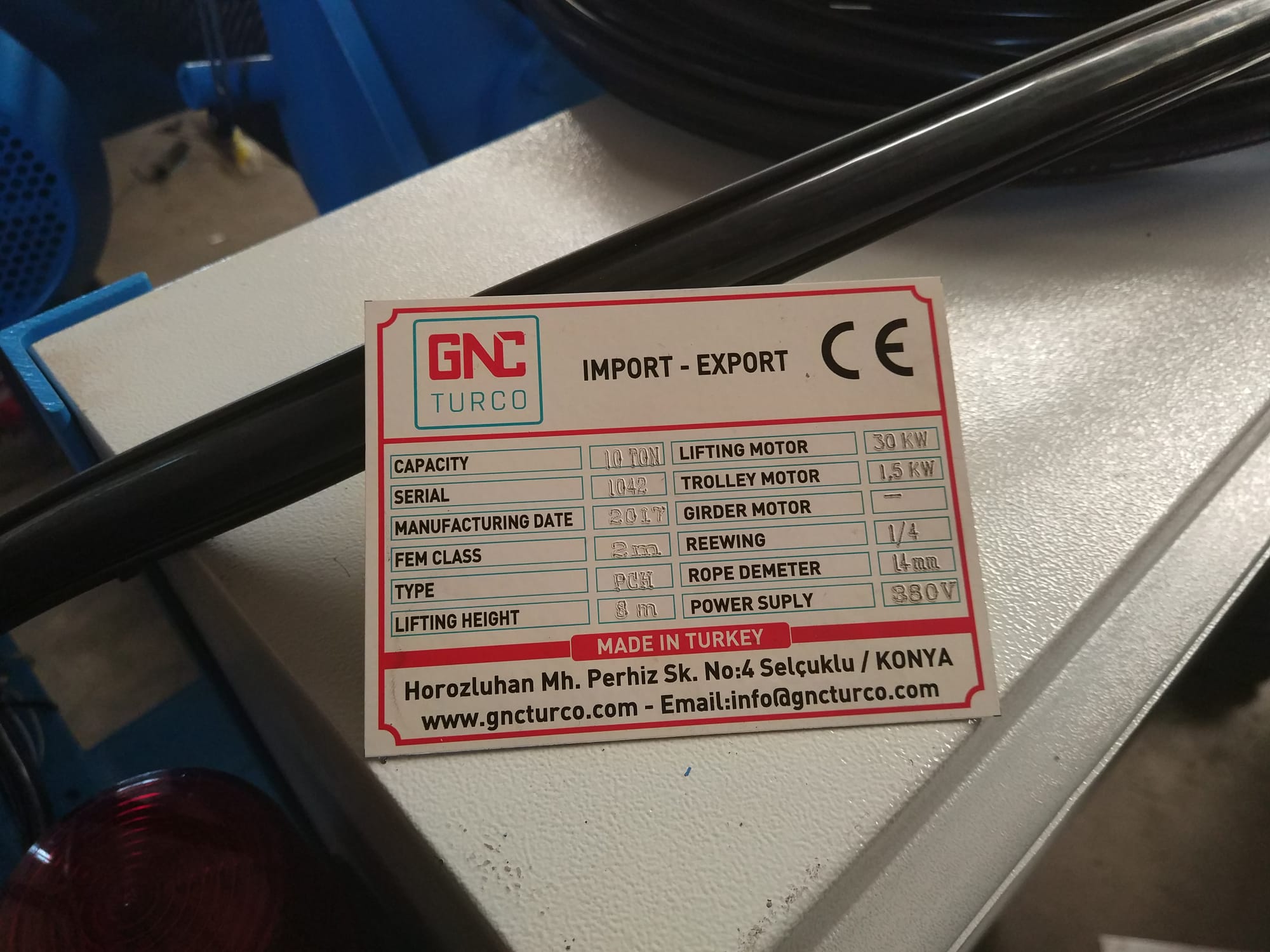

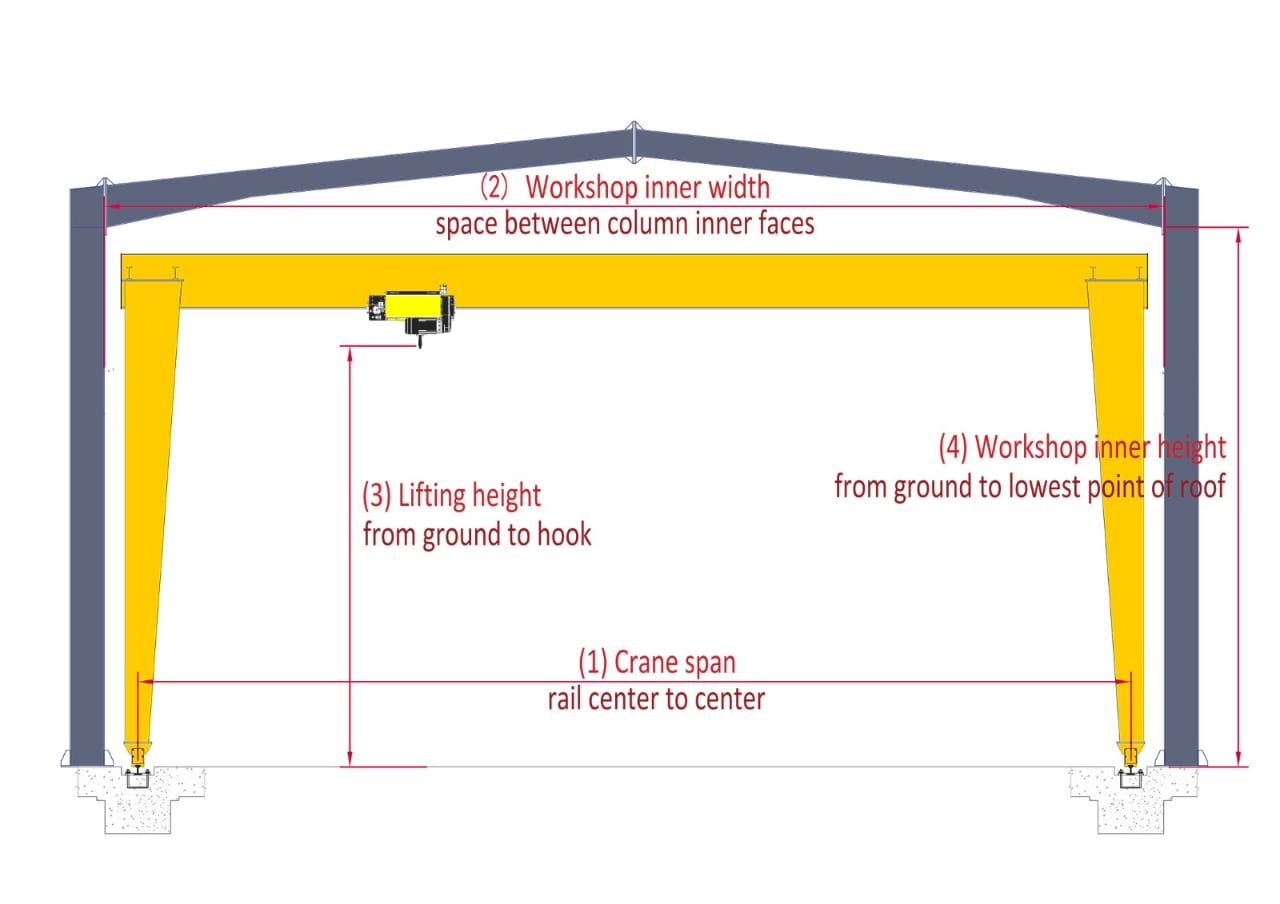

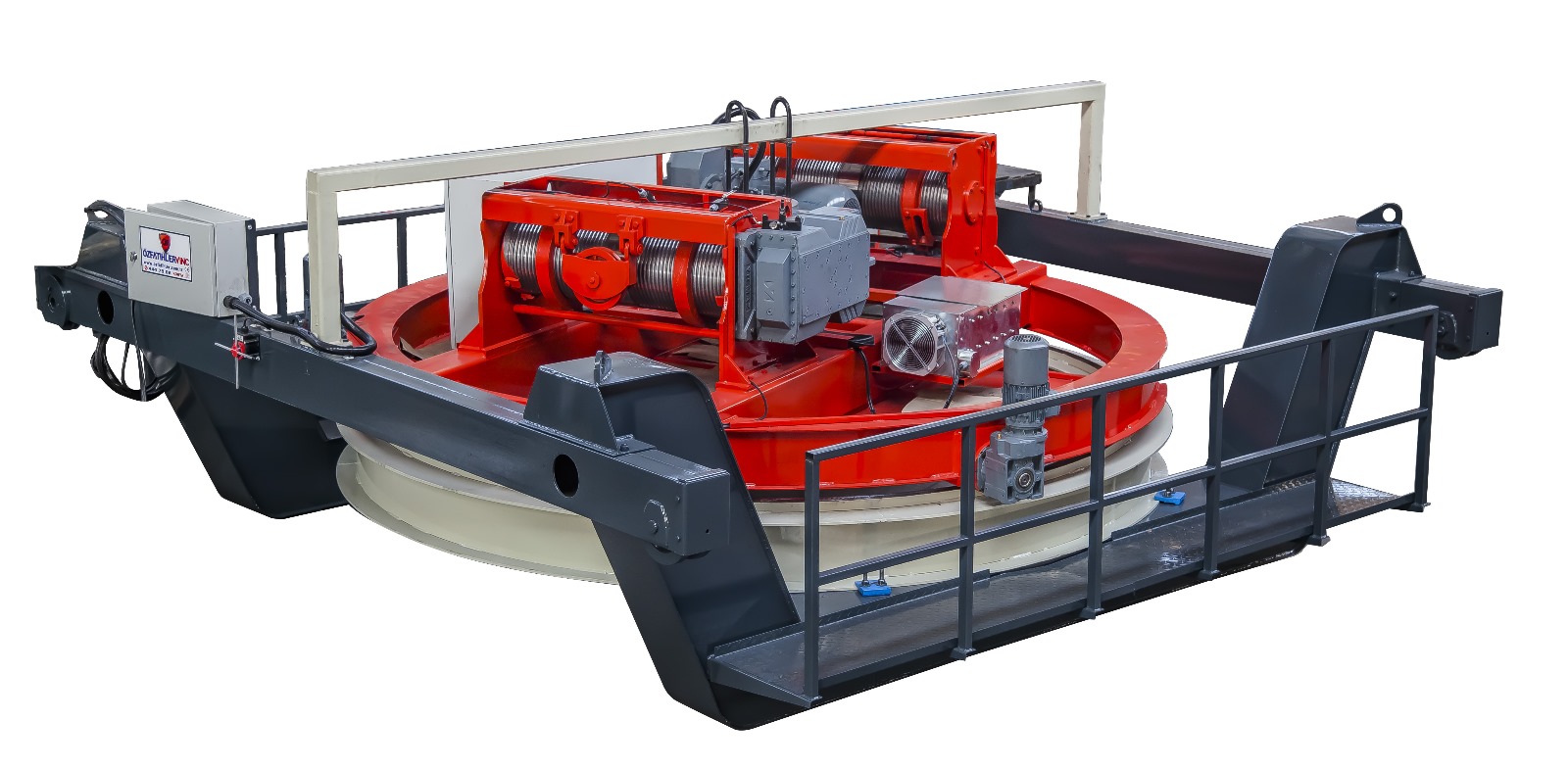

GANTRY CRANE

Double girder gantry cranes are prefered and used in all of industrie in serious manners according to cost, easy maintenance and repair, limitless capacity, limitless dimensions and design and production of desired features are possible due to reasons of reason.

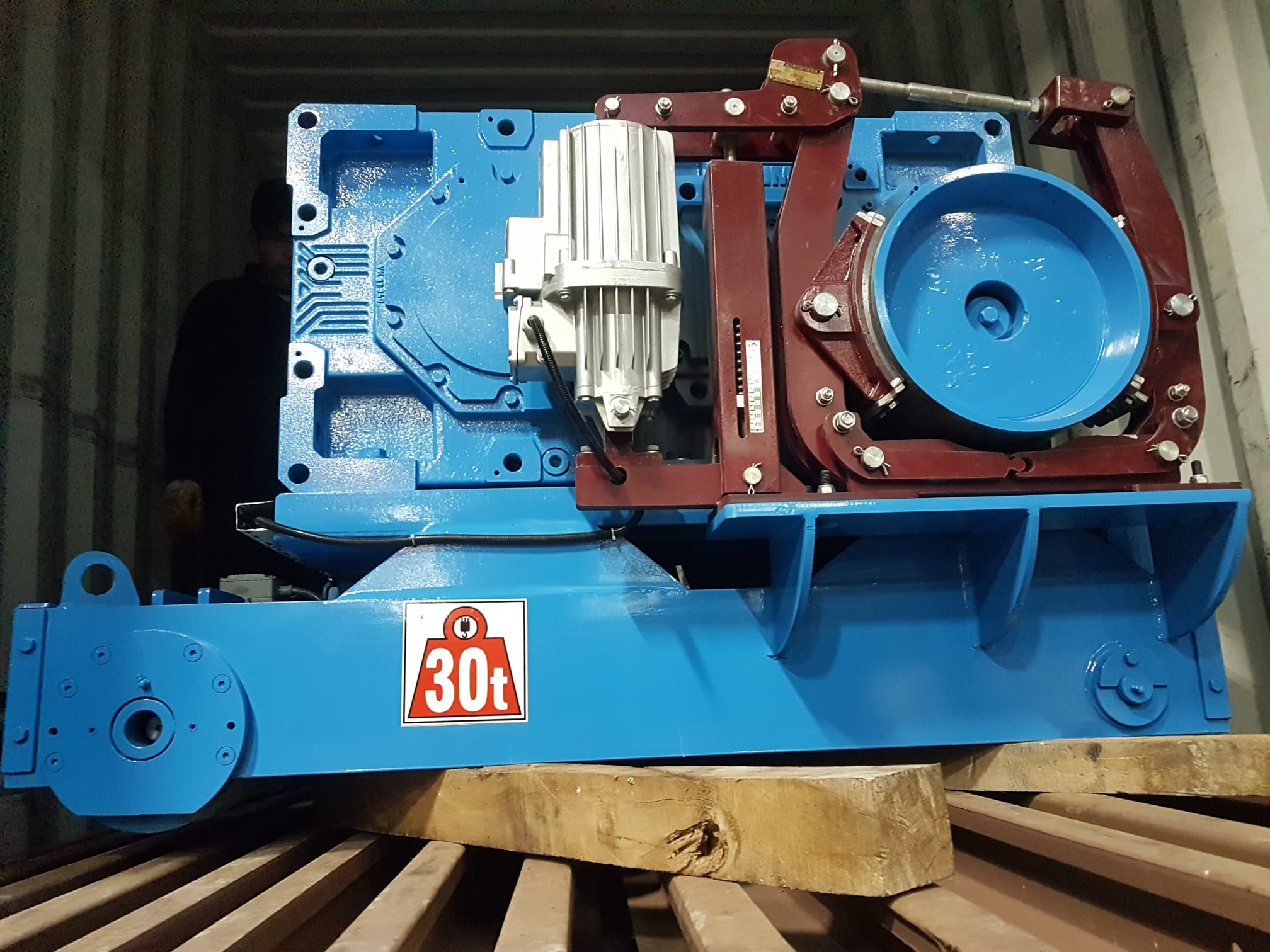

GANTRY CRANE ENDCARRIAGES

Double girder gantry cranes are prefered and used in all of industrie in serious manners according to cost, easy maintenance and repair, limitless capacity, limitless dimensions and design and production of desired features are possible due to reasons of reason.

SPECIAL CRANE

Special cranes are a type of crane system that is designed to meet specific requirements for unique applications.

Factory & Office

FEM & ISO CLASSES

| Yılmaz Reduktor State of Loading |

Km |

Crane Classes (ISO 4301 / 1 • FEM 9.511 / 86) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| T0 | T1 | T2 | T3 | T4 | T5 | T6 | T7 | T8 | ||

| L1 - lıght | 0,125 | M1 (1Dm) | M2 (1Cm) | M2 (1Cm) | M3 (1Bm) | M4 (1Am) | M5 (2m) | M6 (3m) | M7 (4m) | M8 (5m) |

| L2 - MODERATE | 0,25 | M1 (1Dm) | M2 (1Cm) | M3 (1Bm) | M4 (1Am) | M5 (2m) | M6 (3m) | M7 (4m) | M7 (4m) | M8 (5m) |

| L3 - HEAVY | 0,50 | M1 (1Dm) | M2 (1Cm) | M3 (1Bm) | M4 (1Am) | M5 (2m) | M6 (3m) | M7 (4m) | M8 (5m) | — |

| L4 - VERY HEAVY | 1,00 | M2 (1Cm) | M3 (1Bm) | M4 (1Am) | M5 (2m) | M6 (3m) | M7 (4m) | M8 (5m) | — | — |

| Classification and limits of use of the lifting equipment electromechanisms | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Use based on the stress level (type of duty) | Tm = Average duration of daily operation (hours) | ≤ 2 | ≤ 4 | ≤ 8 | ≤ 16 | > 16 | > 16 | ||

| Life span of the mechanisms in 10 years of operation (hours) | 3200 | 6300 | 12500 | 25000 | 50000 | 100000 | |||

| 1) Light | N° max of operating cycles in 10 years of operation (Σ cycles) | 250x10³ | 500x10³ | 100x10³ | 200x10³ | 400x10³ | > 4x10³ | ||

| Tm = Average duration of daily operation (hours) | ≤ 1 | ≤ 2 | ≤ 4 | ≤ 8 | ≤ 16 | > 16 | |||

| 2) Medium | Life span of the mechanisms in 10 years of operation (hours) | 1600 | 3200 | 6300 | 12500 | 25000 | 50000 | ||

| N° max of operating cycles in 10 years of operation (Σ cycles) | 125x10³ | 250x10³ | 500x10³ | 100x10³ | 200x10³ | 400x10³ | |||

| 3) Heavy | Tm = Average duration of daily operation (hours) | ≤ 0.5 | ≤ 1 | ≤ 2 | ≤ 4 | ≤ 8 | ≤ 16 | ||

| Life span of the mechanisms in 10 years of operation (hours) | 800 | 1600 | 3200 | 6300 | 12500 | 25000 | |||

| 4) Heavy | N° max of operating cycles in 10 years of operation (Σ cycles) | 63x10³ | 125x10³ | 250x10³ | 500x10³ | 100x10³ | 200x10³ | ||

| Tm = Average duration of daily operation (hours) | ≤ 0.25 | ≤ 0.5 | ≤ 1 | ≤ 2 | ≤ 4 | ≤ 8 | |||

| Life span of the mechanisms in 10 years of operation (hours) | 400 | 800 | 1600 | 3200 | 6300 | 12500 | |||

| N° max of operating cycles in 10 years of operation (Σ cycles) | 32x10³ | 63x10³ | 125x10³ | 250x10³ | 500x10³ | 100x10³ | |||

| Service group of lifting and travelling mechanisms | as per ISO standard 4301-1 | M3 | M4 | M5 | M6 | M7 | M8 | ||

| as per FEM rule 9.511 | 1Bm | 1Am | 2m | 3m | 4m | 5m | |||

| Intermittent use as per FEDEM rule 9.683 | Hoist mechanisms | Ratio of intermittence (RI%) | 25 | 30 | 40 | 50 | 60 | 60 | |

| Maximum n° of start-ups per hour (A/h) | 150 | 180 | 240 | 300 | 360 | 360 | |||

| Maximum n° of cycles per hour (C/h) | 25 | 30 | 40 | 50 | 60 | 60 | |||

| Ratio of intermittence (RI%) | 20 | 25 | 30 | 40 | 50 | 60 | |||

| Meccanismi del Carrello | Maximum n° of start-ups per hour (A/h) | 120 | 150 | 180 | 240 | 300 | > 360 | ||

| Maximum n° of cycles per hour (C/h) | 20 | 25 | 30 | 40 | 50 | > 60 | |||

| Operation time at main speed (min) | 15 | 15 | 30 | 30 | 60 | > 60 | |||

| Operation time at low speed (min) | 2.5 | 3 | 3.5 | 4 | 5 | 6 | |||

| Max n° of start-ups per hour (A/h) | Maximum n° of start-ups per hour (A/h) | 10 | 10 | 10 | 10 | 10 | 10 | ||

| High speed | 1/3 (33,3% of the total n° of start-ups per hour) | ||||||||

| Low speed | 2/3 (66,7% of the total n° of start-ups per hour) | ||||||||

| Tm = Average duration of daily operation (hours) | Main speed | 2/3 (66,7% of the average duration of daily operation) | |||||||

| Low speed | 1/3 (33,3% of the average duration of daily operation) | ||||||||

Production Side

CHECK OUR GALLERY

Gallery

CHECK OUR GALLERY

Team

CHECK OUR TEAM

Mustafa Genç

GENERAL MANAGER

Hüseyin Genç

Foreign Trade Assistant

İlmir Musin

Russia Factory Partner

İlham Artikov

Uzbekistan Office PartnerContact

To Contact Us

Turkey Office Address

Musalla Bağları Mahallesi Şehit Ahmet Değerli Sokak Dinçtaş İşMrk. NO :11 / 207 Selçuklu Konya

Call Us

Mustafa Genç+90 505 216 02 18

Hüseyin Genç+90 553 382 82 63

Russia Factory Address

Republic of Bashkortostan, Ufa district, village of Vavilovo, Traktovaya st., 19.

Call Us

İlmir Musin+7 901 952 99 99

Uzbekistan Office Address

Taşkent

Call Us

İlham Artikov+998 900 52 44 42